How much does cabinet vision cost software#

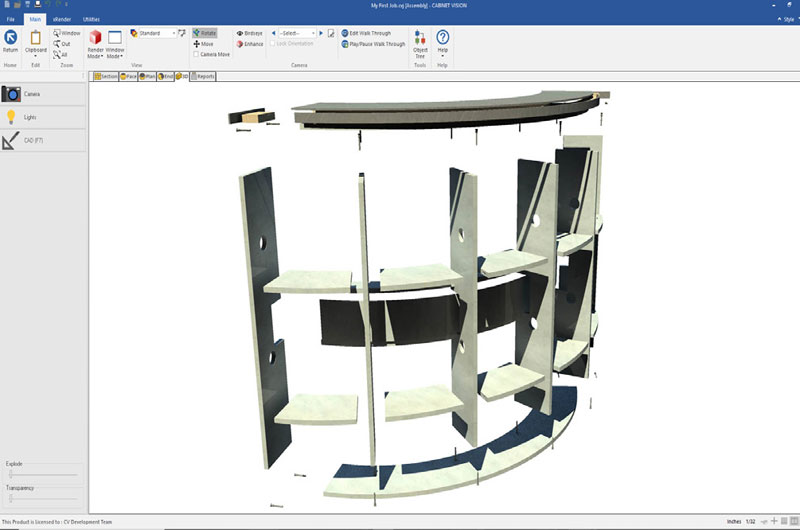

“You can have the best and most powerful software on the market, but if it doesn’t have the right support behind it, it’s no good to you. “We have a first class reputation throughout Ireland for producing bespoke cabinets, and CABINET VISION is a vital part of our service in giving people the exact kitchen they ask for.”Īnd it’s not just the actual CAD/CAM suite from Vero Software that he is impressed with. His design and programming team are mainly former kitchen retailers or fitters, so are readily able to solve any issues regarding customer requests for something that may be particularly difficult to achieve. The software does cost money – but it saves us an awful lot more.” Donal Walshe says: “If we had to manually work out all the cuts, turns, cams and hole positions, and pre-plan every gable, we’d never produce anything. Overall, CABINET VISION’s optimisation and ability to reduce waste are major benefits for both Turin Components’ nesting and beam saw operations, along with speeding up the design process. Previously, we had to program everything at the machines themselves, which was a matter of breaking every cabinet down size by size and programming it individually, which was far more time consuming.” He says: “It’s so simple to set up both processes from information about each panel that’s in the CABINET VISION program. It’s Brendan Sheridan’s role to program both the beam saw and the REM. It also measures out and pre-plans the boring pattern, on their REM boring machine. Reducing waste is another important factor for Donal Walshe when it comes to their Prima EVO beam saw, and he says CABINET VISION makes best use of the sheet by planning out cut patterns more efficiently than proprietary software, and is especially useful if there is a requirement for the grain to go a particular way. “The average nest has between 20 and 30 components, and once I’ve designed them all I nest them on to our standard 2800 x 2700 chipboard sheets, and it keeps waste to an absolute minimum. The former hands-on chippy says it was simple to edit a unit to provide the holes in their unique positioning.Īnother CABINET VISION benefit is optimising material usage.

How much does cabinet vision cost full#

For instance, if it’s a base unit I simply edit the size, depth and height, and then optimise it in Screen-To-Machine and send the NC code to whichever Andi has been assigned to the job.”Īs an example of how easy CABINET VISION handles Turin Components’ bespoke speciality, he cites a recent case where 18 cabinets for a customer’s showroom were all different off-standard sizes, and one of the display units required a full line of 2mm centred holes to fasten dividers in place. If I move a shelf, CABINET VISION automatically moves the shelf studs…if I change a door size it moves all the assolciated fixtures and fittings.

I have a database of existing units in the CABINET VISION library, and it’s so easy to manipulate one of those to come up with what the customer requires.

“I input every job into CABINET VISION, and finalise the design, and type and colour of material, along with drawers and hinges. Padraig Mullin is Project Manager and programmer for the nesting process.

Today they have two Andi nesters programmed by CABINET VISION’s Screen-To-Machine module, and are considering investing in a third next year.

The company also produces hospital cabinets manufactured in the revolutionary waterproof and anti-bacterial material, Sealwise. “The average nest has between 20 and 30 components, and once I’ve designed them all I nest them on to our standard 2800 x 2700 chipboard sheets, and CABINET VISION keeps waste to an absolute minimum.”Īnd having seen how efficient nesting could be on a visit to a company in England, he decided to focus on nesting as the most cost effective way of cutting MFC and MDF carcasses for kitchens, bedrooms, offices, bathrooms and student accommodation. “At the time there were a lot of imported carcasses, but we were the first to manufacture curved units of any shape and size that the customer required. CABINET VISION “Costs Money, But Saves A Lot More,” Says Bespoke Carcass PioneerĪ company which pioneered both bespoke carcasses and nesting in the Irish Republic says the CABINET VISION software which designs their products and drives their two CNC nesters, beam saw and boring machine, means they can produce exactly what customers want, and it saves on waste.ĭonal Walshe saw an opening in the Irish furniture market for bespoke carcasses in 2008, and established Turin Components to begin manufacturing them.

0 kommentar(er)

0 kommentar(er)